The Powder Coating Process: Your Step-by-Step Guide to Lasting Finishes

What Are the Core Steps for Achieving Durable Powder Coated Finishes?

- Surface preparation: We clean, degrease, and profile your substrate to the specified cleanliness and roughness.

- Powder application: We use electrostatic spray or alternate methods to deposit consistent powder thickness.

- Curing and inspection: We bake at the recommended temperature/time window, then rigorously test for adhesion and appearance.

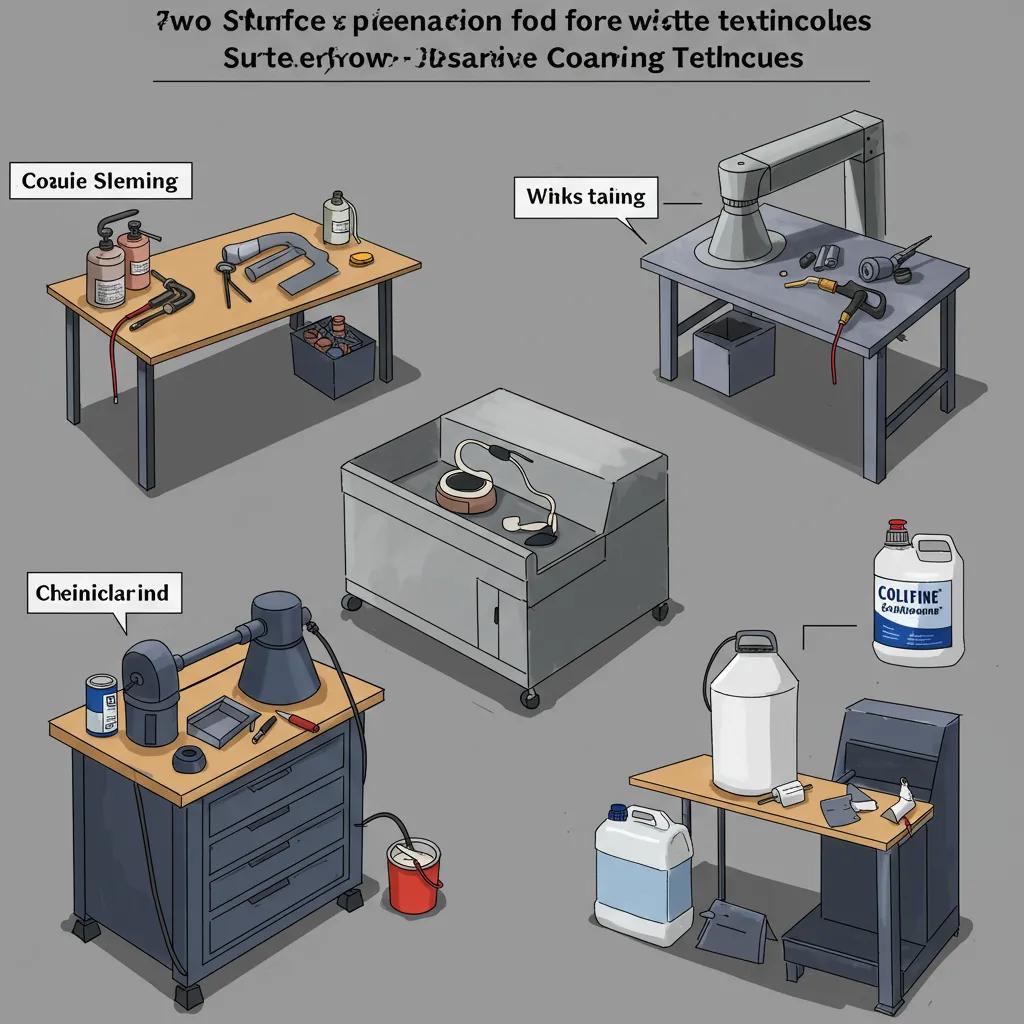

How Does Expert Surface Preparation Guarantee a Quality Powder Coating?

What Happens During Electrostatic Powder Coating Application?

How Do We Perform the Powder Coating Curing Process?

| Resin / Coating Type | Typical Cure Temperature & Time | Resulting Properties and Recommended Ranges |

|---|---|---|

| Epoxy powder (thermoset) | 160–200°C for 10–20 minutes at metal surface | Excellent corrosion resistance and hardness; limited UV stability; ideal for indoor/industrial parts |

| Polyester powder (thermoset) | 180–210°C for 10–20 minutes | Great outdoor durability, color and gloss retention; balanced chemical and impact resistance |

| Thermoplastic (e.g., nylon) | 200–240°C for 5–15 minutes | Melt-fusible system with high toughness and repairability; non-cross-linking, can re-melt at high temp |

What Vital Role Does the Curing Oven Play in Powder Coating?

How Do Temperature and Time Precisely Affect Powder Coating Curing?

What Are Our Common Powder Coating Application Methods?

| Application Method | How It Works | Best Use Cases / Pros & Cons |

|---|---|---|

| Electrostatic spray (corona) | Powder is ionized at the gun and powerfully attracted to grounded parts | Versatile, high transfer for most parts; excellent for thin, even films |

| Electrostatic spray (tribo) | Powder charged by friction in the delivery system | Superior edge coverage on complex shapes; lower gun voltage reduces arcing |

| Fluidized bed | Heated part dipped through a cloud of fluidized powder | Ideal for thick coatings, touch-up, and thermoplastic applications; limited color control |

| Electrostatic fluidized bed | Combination of electrostatic attraction and fluidized medium | Improved thickness control versus plain fluidized bed; perfect for medium-production parts |

How Does Electrostatic Spray Deposition Work for Your Powder Coating?

What Are Our Alternative Powder Application Techniques?

What Are the Key Business Benefits of Powder Coating?

- Unmatched Durability & Reduced Maintenance: Our long-lasting film significantly reduces repair cycles and replacement costs.

- Superior Corrosion Resistance: Cross-linked thermoset powders form incredibly effective barriers against oxidation and chemical exposure.

- Environmental & Operational Efficiency: Low VOCs and powder reclaim lower environmental impact and disposal costs, boosting your bottom line.

| Coating Type | Durability / VOC / Cost over Time | Value |

|---|---|---|

| Powder coating (thermoset polyester) | High durability; low/zero VOC; moderate initial cost, significantly lower lifecycle cost | Extended service life and substantial maintenance savings |

| Powder coating (epoxy) | Excellent corrosion resistance; low VOC; limited UV stability | Ideal for indoor industrial equipment with demanding long-life needs |

| Liquid paint (conventional) | Variable durability; higher VOCs; lower upfront cost but often higher lifecycle cost | Useful for quick touch-up jobs or low-durability requirements |